Policy-Driven Technological Upgrade: Industrial Lifting Sling Industry Welcomes New Opportunities in 2025

The global industrial Lifting Sling market is entering a phase of accelerated expansion, driven by China’s vigorous implementation of the *Promotion of Large-Scale Equipment Update Action Plan*. Industry analysts project 2025 to be a watershed year, with policy mandates, technological breakthroughs, and emerging international opportunities converging to reshape the sector.

Policy-Driven Market Expansion

China’s equipment modernization initiative has catalyzed unprecedented demand for advanced lifting solutions. According to the China Heavy Machinery Industry Association, the sector’s import-export volume surpassed ¥40 billion ($5.5 billion) in 2024, setting a historic record. Notably, lifting equipment and accessories constituted 35% of this total, underscoring their strategic role in industrial infrastructure. The policy’s stringent requirement to phase out lifting machinery older than 10 years—coupled with incentives for adopting energy-efficient and intelligent systems—is creating a dual demand surge: replacement cycles for conventional equipment and adoption of next-generation solutions.

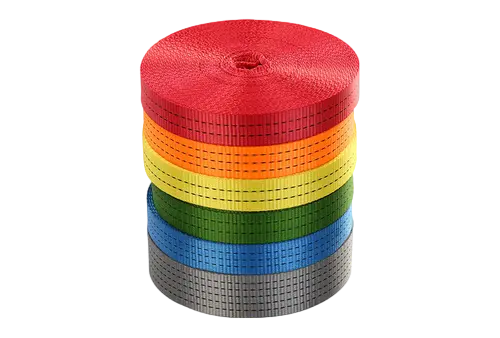

High-strength synthetic fiber slings are emerging as primary beneficiaries, with their corrosion resistance, weight efficiency, and adaptability to automated systems aligning perfectly with modernization goals. Industry estimates suggest the policy could unlock an additional ¥15 billion ($2.1 billion) in domestic demand by 2026.

Technological Leapfrogging

The synthetic fiber sling segment is undergoing a paradigm shift toward high-performance materials and smart manufacturing. Global Market Insights forecasts the sector to grow at a 12% CAGR through 2030, propelled by innovations in polymer science and IoT integration.

A case in point is the EN1492-1-certified sling developed by domestic innovator [Company Name], which employs patented high-density weaving technology to achieve a 300-ton load capacity—a 40% improvement over conventional designs. Deployed in 23 glass factories across Shandong and Guangdong provinces, these slings have enabled direct transportation of naked glass bundles, slashing packaging costs by 30% while reducing carbon emissions from secondary materials.

Safety Standards Reshaping Competitive Dynamics

The implementation of the *Crane Safety Regulations (GB/T 3811-2023)* is triggering a fundamental shift from price-based to value-driven competition. The updated code mandates:

1. Mandatory digital traceability for all lifting components

2. 50% higher safety factors for critical infrastructure projects

3. Annual third-party certification for slings used in hazardous environments

These requirements are disproportionately impacting small-scale manufacturers lacking R&D capabilities, with industry consolidation accelerating—the top 5 players now control 68% of China’s high-end sling market, up from 52% in 2020.

Globalization 2.0: Belt and Road Opportunities

While domestic demand surges, Chinese manufacturers are making strategic inroads into international markets. Southeast Asia’s lifting sling market, growing at 20% annually, presents particular promise as regional infrastructure projects under the Belt and Road Initiative (BRI) intensify. Key developments include:

- Malaysia’s $7.2 billion Pan Borneo Highway requiring 12,000+ heavy-duty slings

- Vietnam’s LNG terminal expansions driving demand for marine-grade slings

- Indonesia’s new capital Nusantara project necessitating earthquake-resistant rigging solutions

Sustainability Imperative

Environmental considerations are becoming a core competitive metric. The European Union’s upcoming Carbon Border Adjustment Mechanism (CBAM) is pushing manufacturers to adopt green production methods. Industry frontrunners are responding with:

- Slings made from 100% recycled PET fibers

- Solar-powered manufacturing facilities

- Blockchain-based carbon footprint tracking

As the industry stands at the intersection of policy tailwinds and technological disruption, stakeholders who prioritize innovation, safety, and sustainability are poised to dominate the next era of global industrial growth. With projected global market value reaching $8.7 billion by 2027, the lifting sling sector exemplifies how traditional manufacturing can reinvent itself through strategic alignment with macro trends.