0102030405

150T HEAVY LOAD eye to eye round sling!

2025-06-25

Eye-to-eye round slings, also known as endless round slings, offer several significant advantages over other types of Lifting Slings, such as wire rope slings or chain slings. Here are some of the key benefits:

Safety:

- High Strength-to-Weight Ratio: Round slings are incredibly strong relative to their weight. This makes them easier and safer to handle than heavier alternatives, reducing the risk of strain or injury to workers.

- Soft and Gentle: The synthetic fibers of round slings are much softer than steel, minimizing the risk of damage to the load being lifted. This is particularly important when lifting delicate or polished surfaces.

- No Kinks or Sharp Edges: Unlike wire rope or chain slings, round slings have no sharp edges or kinks that could damage the load or injure workers.

- Visual Inspection: The protective cover of a round sling allows for easy visual inspection. If the cover is damaged, it’s a clear indication that the sling should be removed from service.

- Reduced Snagging: The smooth, rounded surface of the sling minimizes the risk of snagging on the load, further improving safety.

Performance and Versatility:

- Conform to Load Shape: Round slings are flexible and easily conform to the shape of the load, distributing the lifting force evenly and minimizing stress points.

- Easy to Rig: Their lightweight and flexible nature make round slings easy to rig, even in tight spaces.

- Choke Hitch Capability: The endless design allows for easy choke hitching, providing a secure and versatile lifting method.

- Rotation of Wear Points: The ability to rotate the sling regularly distributes wear evenly, extending its lifespan. Simply moving the position of the sling on the load can significantly increase its usable life.

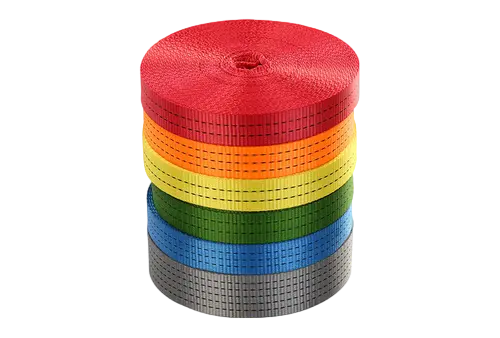

- Color-Coded for Capacity: Round slings are typically color-coded according to their load capacity, making it easy to identify the correct sling for the job. (Following safety standards of course)

- High Abrasion Resistance (with proper sleeve/cover): The outer cover protects the load-bearing core from abrasion, extending the sling’s lifespan. Certain cover materials offer even greater resistance to wear.

- Non-Conductive: Unlike metal slings, round slings are non-conductive, making them safer to use in electrical environments. (Though always verify with manufacturer specifications).

Cost-Effectiveness:

- Long Lifespan: With proper care and maintenance, round slings can have a long lifespan, making them a cost-effective lifting solution.

- Reduced Damage to Loads: The soft and gentle nature of round slings minimizes damage to loads, reducing the risk of costly repairs or replacements.

- Lower Maintenance Costs: Round slings require less maintenance than wire rope or chain slings.