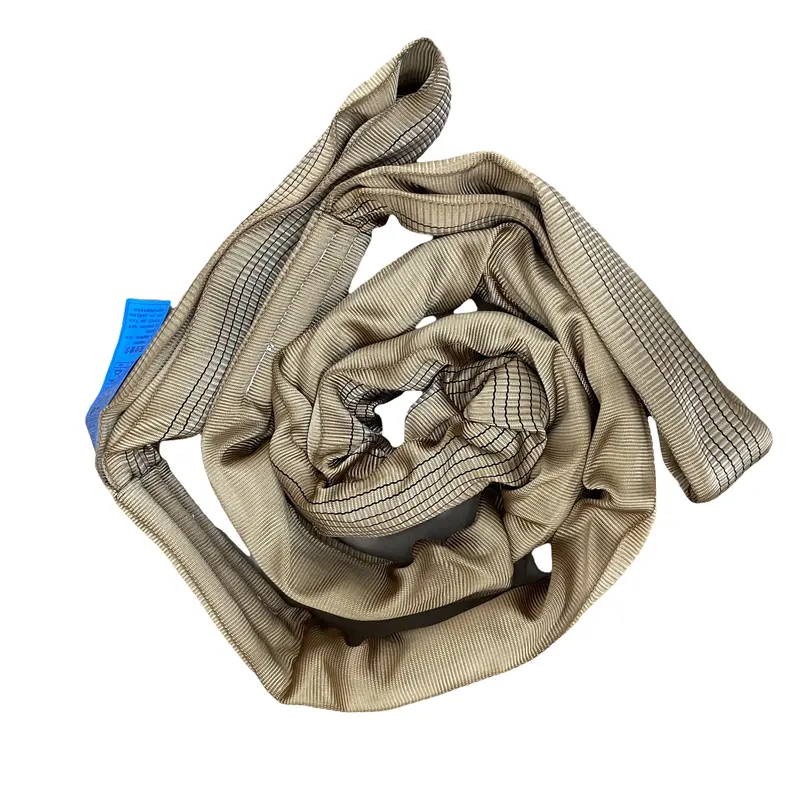

High Class Eye to Eye Tubular Sling- Medeer Eye&Eye Polyester Load-Lifting Sling - Rated Capacity 6 Ton

Features

• High-Strength Polyester Core Construction

• Optional abrasion-resistant and cut-resistant protective sleeves

• Lightweight and flexible for easy operation in confined spaces

• Color-Coded Capacity Identification

• Each sling carry a blue label giving correct WLL for different load connection methods and angles

• Smooth surface contact prevents damage to delicate surfaces

• Capacity range: 1-300 tons; Effective length: 0.5-80 meters

• Easy to connect: Double-eye design is convenient for connecting with lifting tools such as hooks and shackles.

applications

Lifting steel beams / Installation of air conditioning units / Assembly line equipment / Securing cargo on board / Loading and unloading containers and cargo / Hoisting stage lighting

Construction & Engineering

Cargo Transportation

Equipment Installation

Equipment Installation

description

Engineered for precision lifting operations, our 6-ton (6T) double-eye tubular sling redefines industrial safety and efficiency with its advanced construction and compliance with EN 1492-2 standards. Designed for demanding environments, this sling combines a 7:1 safety factor (42-ton break strength) with exceptional flexibility, making it ideal for handling delicate or irregularly shaped loads while ensuring operator confidence.

Core Technology & Construction

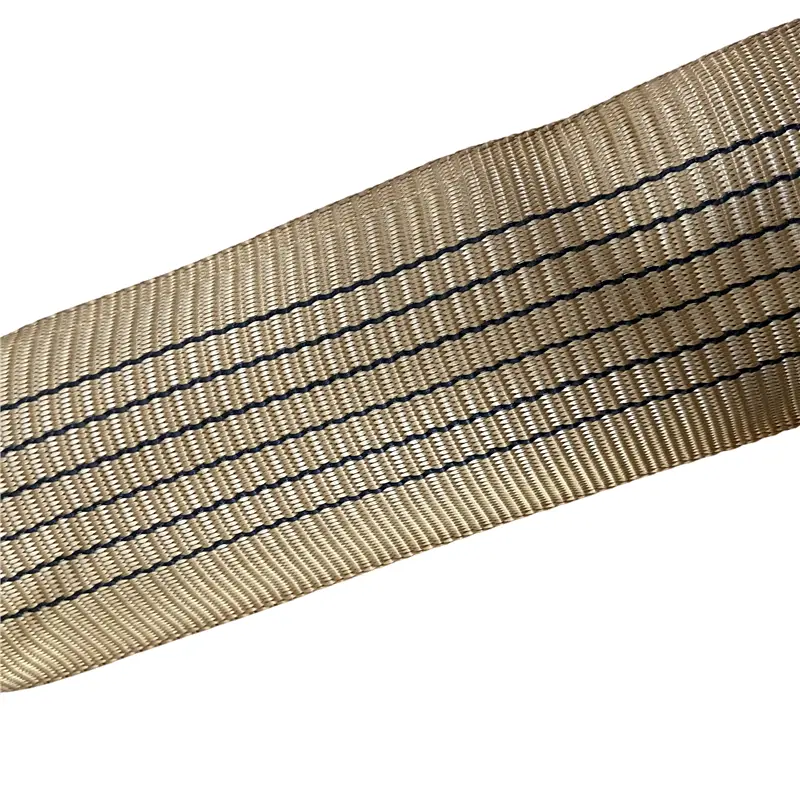

Crafted from ultra-high-tenacity polyester multifilament yarns, the sling features a seamless tubular design where the load-bearing core is fully encapsulated within a durable protective sleeve. This innovative structure isolates the core yarns from direct contact with abrasive surfaces, eliminating strength loss caused by friction while maintaining 100% of the rated capacity. The interlocked tubular weave ensures uniform stress distribution across all filaments, achieving maximum tensile strength (42T MBS) without compromising flexibility.

Crafted from ultra-high-tenacity polyester multifilament yarns, the sling features a seamless tubular design where the load-bearing core is fully encapsulated within a durable protective sleeve. This innovative structure isolates the core yarns from direct contact with abrasive surfaces, eliminating strength loss caused by friction while maintaining 100% of the rated capacity. The interlocked tubular weave ensures uniform stress distribution across all filaments, achieving maximum tensile strength (42T MBS) without compromising flexibility.

Key Performance Features

7:1 Safety Assurance: Exceeds industry requirements with a calculated 42-ton minimum break strength (6T WLL).

Surface-Friendly Operation: Non-abrasive, non-conductive sleeve prevents scratches on polished metals, painted surfaces, and fragile cargo.

360° Load Adaptability: Flexible tubular structure conforms to irregular shapes (pipes, machinery parts, artwork) while maintaining optimal load contact.

Dual Reinforced Eyes: Computer-controlled splicing creates uniform 200mm diameter eyes with triple-stitched reinforcement for secure hook/shackle connections.

Environmental Resistance: UV-stabilized and chemically inert materials withstand temperatures from -40°C to 100°C.

7:1 Safety Assurance: Exceeds industry requirements with a calculated 42-ton minimum break strength (6T WLL).

Surface-Friendly Operation: Non-abrasive, non-conductive sleeve prevents scratches on polished metals, painted surfaces, and fragile cargo.

360° Load Adaptability: Flexible tubular structure conforms to irregular shapes (pipes, machinery parts, artwork) while maintaining optimal load contact.

Dual Reinforced Eyes: Computer-controlled splicing creates uniform 200mm diameter eyes with triple-stitched reinforcement for secure hook/shackle connections.

Environmental Resistance: UV-stabilized and chemically inert materials withstand temperatures from -40°C to 100°C.

Operational Advantages

The lightweight design (up to 40% lighter than chain alternatives) reduces worker fatigue during repetitive lifting tasks while enabling precise load positioning. Its pliable nature allows for safe rigging around sharp edges through proper use of corner protectors. The bright color-coded sleeves (available in orange, green, or custom hues) enhance jobsite visibility and capacity identification.

The lightweight design (up to 40% lighter than chain alternatives) reduces worker fatigue during repetitive lifting tasks while enabling precise load positioning. Its pliable nature allows for safe rigging around sharp edges through proper use of corner protectors. The bright color-coded sleeves (available in orange, green, or custom hues) enhance jobsite visibility and capacity identification.

Industrial Applications

Proven effective in:

Steel beam erection in construction sites

Machinery relocation in manufacturing plants

Offshore cargo securing

Theater rigging for lighting/sound equipment

Automotive component handling

Renewable energy turbine assembly

Proven effective in:

Steel beam erection in construction sites

Machinery relocation in manufacturing plants

Offshore cargo securing

Theater rigging for lighting/sound equipment

Automotive component handling

Renewable energy turbine assembly

Maintenance & Safety

Each sling undergoes individual load testing and ships with a traceable serial number for compliance documentation. The abrasion-resistant sleeve features wear-indicator threads that visibly signal when retirement thresholds are reached. For prolonged service life, the sling resists mildew growth and requires only simple inspections for cuts, heat damage, or chemical exposure.

Each sling undergoes individual load testing and ships with a traceable serial number for compliance documentation. The abrasion-resistant sleeve features wear-indicator threads that visibly signal when retirement thresholds are reached. For prolonged service life, the sling resists mildew growth and requires only simple inspections for cuts, heat damage, or chemical exposure.

Why Choose Our Tubular Sling?

Ergonomic Handling: Soft-grip sleeve textures enable secure barehanded operation

Global Certification: Supported by third-party test reports from TUV/SGS/BV

Ergonomic Handling: Soft-grip sleeve textures enable secure barehanded operation

Global Certification: Supported by third-party test reports from TUV/SGS/BV

Optimize your material handling operations with this intelligent lifting solution that bridges the gap between heavy-duty capacity and delicate-load sensitivity. occasions. It can improve work efficiency, reduce operational risks, and protect the safety of the objects being lifted.

Structure